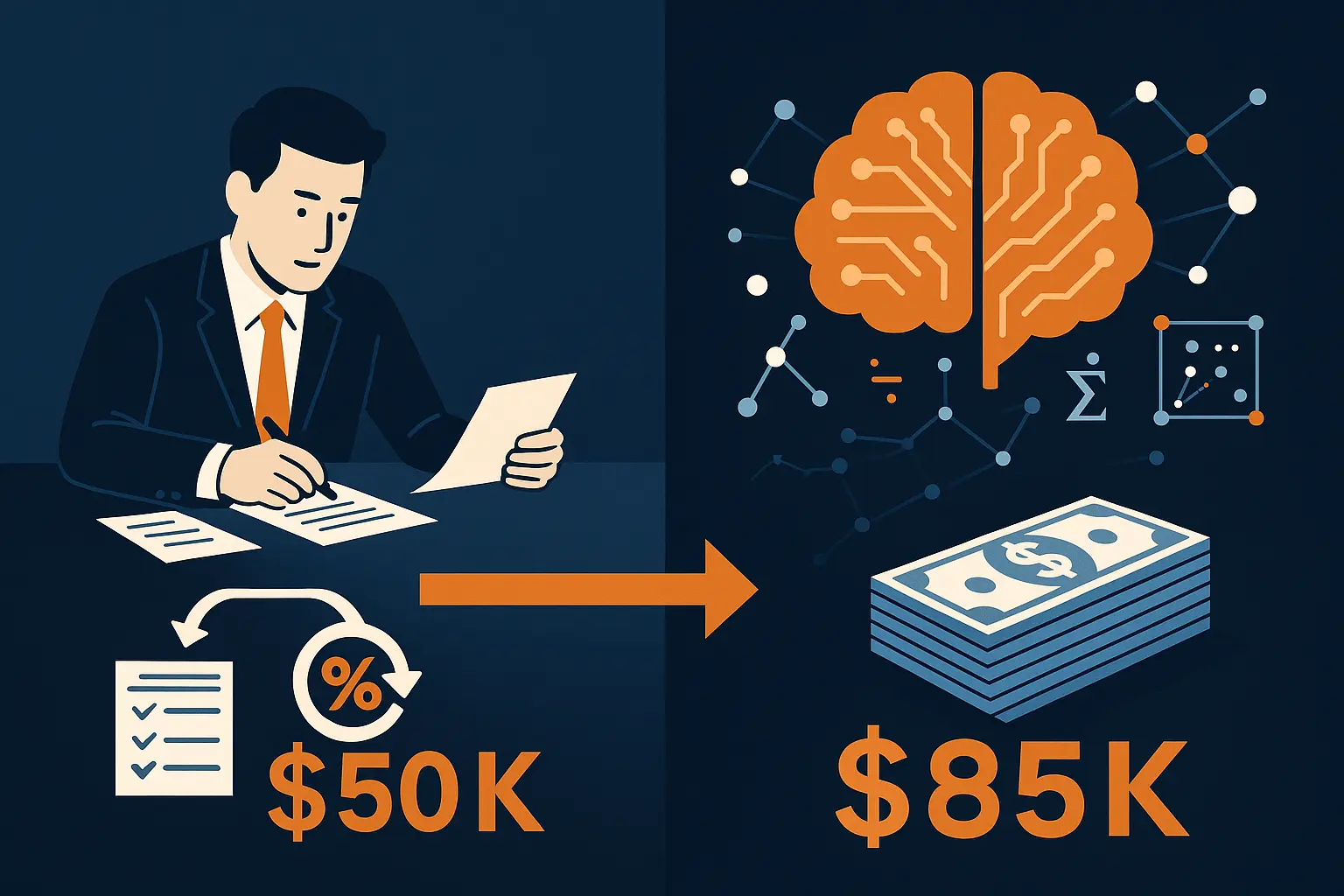

Duty drawback is one of the few compliance tools that can directly increase your bottom line. But most companies don’t get back nearly as much as they could because most brokers don’t know how to optimize for maximum refund value.

That’s not to say they’re doing anything wrong. It’s because true drawback optimization isn’t a rote filing process—it requires applied mathematics.

Calculating the highest possible refund means choosing the right drawback provision (1313(j)(1) vs. 1313(j)(2)), understanding when substitution rules help or hurt you, sequencing imports and exports in the most efficient way, and allocating limited inventory across unused and manufacturing claims—things most brokers are equipped to handle. Rather, they require optimization engineering instead of the more common forms and spreadsheets.

At Pax, that’s exactly what we’ve built for. Our system doesn’t just file your drawback claim, it runs millions of simulations across your data to identify the highest-value path. And it does this using logic and tools no manual broker can replicate.

In this article, we’ll walk through several of the high-level concepts behind drawback optimization:

- What drives refund value for each provision (J1 and J2)

- Why substitution claims can leave so much money on the table

- How to optimize across both unused and manufacturing claims

- Why Pax is the only platform designed to actually do all this for you

This isn’t a step-by-step how-to guide. It’s a window into the strategy and structure behind advanced drawback logic—and a look at where refund value can quietly get lost, even in well-run programs. If you currently file drawback, your broker might be leaving some refunds on the table. And if you’re a broker, you might not be unlocking the full refund value your clients are eligible for.

J1 vs. J2: choosing the right provision

When it comes to unused merchandise drawback, the kind where imported goods are exported without being transformed, the first major decision is whether to file under J1 (direct identification) or J2 (substitution). This choice shapes your refund amount more than almost anything else in the claim.

What is J1 (direct identification)?

J1 is the more straightforward method—you identify the exact goods you imported and match them to the exact goods you exported. This requires either serial number tracking or clear accounting practices like first-in-first-out (FIFO) or lot-level tracking.

Because you’re linking the same physical goods, the refund you get under J1 is based on the actual duties paid on those imports. That means your refund is precise and usually higher per unit than under substitution. But J1 has a catch, it only works if you can prove the match. For many businesses with bulk or blended inventory, that can be a challenge.

For example, let’s say you import 500 units of high-grade steel tubing at $10/unit, paying a $1 duty per unit. If you later export 200 of those exact same units (and can prove it through inventory tracing) your refund is simply calculated using the export price of $200. No ambiguity, no substitution logic needed.

What is J2 (substitution)?

J2 allows more flexibility. Instead of proving it’s the exact same item, you only need to show that the imported and exported items share the same 8-digit HTS code (and meet other substitution rules). That opens the door for refund eligibility even when exact tracing isn’t possible.

But that flexibility comes with a downside. Customs calculates your refund based on the lesser of the import or export value. So if you imported high-value goods but exported lower-cost equivalents, you won’t recover the full duty you originally paid. And if your broker simply files matches in date order without analyzing the price variance across your shipments, you could be losing a lot of money.

Imagine you import two different types of frozen tuna, both classified under Chapter 03 (Fish and crustaceans) but with different species codes. Batch A is Atlantic and Pacific bluefin tuna (HTS 0303.45.01), a premium product valued at $100 per pound. Batch B is skipjack tuna (HTS 0303.43.00.00), a much lower-value species at $70 per pound.

If you export the $100/lb bluefin but your broker matches it against the $70/lb skipjack import as a substitution under 19 U.S.C. 1313(j)(2), your drawback refund will be calculated on $70—the lesser of the two values—not the $100 you actually shipped.

Now imagine that same broker simply goes down the list matching in order—first import equals first export. That kind of lazy matching can easily cost you thousands of dollars in lost refund value.

Strategic implications: picking between J1 and J2

Most brokers treat the question of J1 vs. J2 as a one-time decision based on how well-organized your documents are and how easy it will be to file J1. In reality, each shipment or entry line can (and should) be evaluated individually. You can file both types of claims within a single program, as long as you don’t reuse the same import line across both.

At Pax, our system runs simulations across your entire dataset to identify where:

- A direct match (J1) gives you a cleaner, higher-value refund

- Substitution (J2) is your only option, but we can still maximize the value by matching intelligently

The result? You don’t need to choose one method. You just need to choose the one that gets you the most money for each unit.

Why J2 substitution claims lose value and how to fix it

J2 drawback is powerful. It allows importers to claim refunds on exported goods even if they cannot match it to imports that are the exact same physical units as long as they share an HTS code. But once again, there’s a catch. It’s easy to file in a way that’s compliant, yet far from optimal.

Most brokers follow a basic matching logic by pairing the first available imports with the first eligible exports, walking line by line down a spreadsheet. It works. But it’s almost always leaving refund dollars on the table.

At Pax, we’ve found that two specific traps cause most of the loss:

- The value trap: refund is calculated on the cheaper of import vs export

- The date trap: poor matching order wastes valid pairings

Trap 1: value-based refunds punish lazy matching

In J2, Customs calculates your drawback based on the lower value between the imported good and the exported good.

That means if you import high-end product A and match it in substitution filing to a cheaper version of product A exported, even with the same HTS code, you’ll only be refunded based on the cheaper one.

For example, let’s say on January 2, 2024, you imported custom-designed microchips for $180/unit, then on February 1, 2024, you exported generic bulk chips under the same HTS code, worth $95/unit. If you match those two? You just paid duties on the $180 unit, but you’re getting refunded on the $95 one.

Now imagine later in your records, it shows that you actually exported more premium microchips later in the year—the original $180 import would be much better matched in substitution to that batch of exports, but it will be impossible for any broker going down the list matching thousands of entries manually to remember, go back, then pair those premium batches up optimally. They are dealing with too much information.

Most brokers will simply follow a FIFO or date-based logic to create these pairings. It’s fast and easy to audit, but it’s not optimized for value. Brokerage firms’ most commonly used drawback calculators, such as DutyCalc, follow similar nonoptimal one-pass processes to make substitution pairings.

With Pax, our system runs full-scale simulations across every valid combination of imports and exports, we don’t just match by HTS code and date. We model refund outcomes at the unit level, optimizing across millions of possible paths to pick the one that gets you the highest possible drawback.

Trap 2: the date constraint can quietly kill good matches

The second major trap when optimizing unused substitution drawback under J2 is date sequencing. Many brokers or traditional drawback tools will simply look down the list of imports and exports and match the first eligible pair they find. But this approach can accidentally throw away valuable opportunities because export dates must come after import dates.

Here’s a simplified example to show what we mean:

Above you'll see:

- Three imports (blue), occurring in 2022 and 2025

- Three exports (pink), all in 2024 or 2025

- Circle size = quantity of goods

It looks like a clean match: 3 in, 3 out. But here’s where such a nonoptimal system goes wrong.

This is what many brokers or systems like DutyCalc do—match the first available import to the first eligible export. But look closer, two of the imports (dated Jan 2, 2025) are being paired with exports that occurred before them (Jan 1, 2024 and Jan 1, 2025). Since exports must happen after imports, these matches are invalid, which means two whole import-export units go to waste.

Now here’s the optimized approach Pax uses. We intelligently search all possible combinations to find the valid sequence that maximizes total refunds. This matches earlier-dated imports to earlier exports, and preserves the ability to match later imports with later exports. Now all six units are matched successfully.

Keep in mind this is a constructed example, where the optimal solution may seem obvious. In the real world brokers might have to deal with thousands of import/export records across multiple HTS codes, each with their own constraints. Traditional systems just can’t solve that efficiently. Pax can—because we’ve engineered it to.

Mixing J1 and J2 within a single claim

One of the most powerful, and too often underutilized, strategies in unused drawback is mixing J1 (direct identification) and J2 (substitution) within the same claim. Most brokers don’t do this. Many don’t even realize you can.

But when executed correctly, this hybrid strategy can unlock significantly higher refund values, especially in complex import-export environments. It requires careful logic, line-by-line decision making, and a deep understanding of how U.S. Customs and Border Protection (CBP) calculates value under each provision.

That’s exactly what Pax was built to do.

You don’t have to choose one or the other

CBP allows you to use both J1 and J2 provisions in the same claim, as long as you don’t double count. That means you can’t use the same import entry line under both provisions. But you can (and should) evaluate which provision gives you the better outcome for each line.

Think of J1 as your high-certainty refund method: great when you can trace the exact unit of a product from import to export. Think of J2 as your flexible backup plan: useful when tracing is hard, but the HTS code is consistent and your documentation is clean.

The key is to blend the two strategically.

Example: apparel manufacturer with mixed inventory

Let’s say a U.S. company imports 2,000 units of fabric rolls at $20 each from South Korea. They use 1,200 of those in finished garments, trackable by lot number. The other 800 are mixed into a larger inventory pool alongside U.S.-made fabrics and exported in bulk.

With most brokers, this situation might get filed all under J2—or worse, only the 800 units might get filed, because they’re easier to substitute. Either way, refund value is lost.

Pax does it differently:

- The 1,200 traceable rolls are filed under J1, where we can prove a direct import-export link and refund the actual $20/unit duty paid.

- The remaining 800 go under J2, matched flexibly to export batches by HTS code and optimized by prices and dates.

This hybrid filing allows the company to recover the maximum refund across both segments of inventory without wasting any eligible duty paid.

Why most brokers don’t do this

The challenge isn’t regulatory as CBP permits it. The challenge is structural.

Most brokers don’t have software that supports line-level provision logic. They either default to J2, or split claims artificially (often at great cost to the client) to keep their internal systems clean. That means a lot of money is left on the table.

At Pax, we’re a dedicated duty drawback company, so our logic engine evaluates every eligible import against every export using:

- Line-level traceability checks

- HTS code overlap and pricing logic

- Export sequencing (to comply with date rules)

- Simulated outcomes under both J1 and J2

Then we allocate each line to whichever provision gets you the higher refund. Without overlap, without manual bottlenecks, and without missing eligible duty.

Why it matters

Let's say J1 nets you $24,000, J2 nets you $26,000, but a blended J1 + J2 approach nets $32,000. That extra $6,000 is the difference between basic compliance and optimization. And quarter after quarter that delta compounds.

If you're not mixing provisions, you're likely walking away from 10–40% of the value you're entitled to.

Mixed provisions: manufacturing + unused

In real-world trade operations, very few companies operate with clean, siloed categories of "unused" or "manufactured" goods. Shipments often include components that serve multiple purposes. Some are exported in their original form, while others are transformed into finished products before export. This hybrid reality is what CBP refers to as mixed provisions, and it represents one of the most overlooked areas for refund optimization.

Understanding how to allocate your imported goods between the unused and manufacturing buckets is not just a matter of compliance—it’s a matter of maximizing refund value. Done well, this decision can unlock hundreds of thousands, or even millions, of dollars. Done poorly, it can quietly erase value from your books without you ever realizing it.

What are mixed provisions?

Under drawback law, you’re allowed to claim refunds under two distinct categories:

- Unused drawback applies when you export a product in substantially the same condition in which it was imported.

- Manufacturing drawback applies when you import raw or intermediate goods, use them in a manufacturing process, and then export the resulting finished product.

Here’s the key rule: you cannot double-claim an imported item. If a good is used in manufacturing, it cannot also be claimed as unused, and vice versa. However, many shipments or inventory pools contain items that are ultimately used in both ways. That’s where mixed provisions come in, you’re essentially allocating your imports strategically across both tracks.

A realistic example: car parts and finished cars

Consider a company that imports 100 units of car parts from overseas. It also buys 50 additional units domestically. The company then manufactures 70 finished cars using parts from the combined pool (imported + domestic) and separately exports 80 car parts unused, without modifying them.

At this point, the company is eligible to file for drawback on up to 100 total units of imported car parts. Why? Because that's all they brought in from abroad. But they face a strategic question: how should those 100 units be split across the 70 cars (manufactured category) and the 80 raw parts (unused category)?

This is not just a bookkeeping exercise—it directly impacts the size of the refund check.

Refund math: why this decision matters

When goods are filed under the unused drawback category (J1 or J2) the refund is calculated based on the actual duty paid at import. If the imported car parts were expensive, or sourced from a high-duty country, the refund here might be substantial.

By contrast, the manufacturing drawback refund is often governed by what’s called a schedule rate. This is a standard refund estimate determined by Customs for that type of manufactured product. Instead of reflecting the actual duties paid on the underlying parts, it reflects a generic average—often lower than your true cost basis, especially for companies that import high-spec components.

So, if your actual import duties were higher than the schedule rate, you’re likely better off classifying more volume as unused, to take advantage of the more generous refund. If the schedule rate is surprisingly high—or if your imported cost basis is unusually low—you might lean into the manufacturing category instead.

Why most brokers miss this

The problem is, most brokers don’t run this analysis. They either file everything as unused, assuming it’s simpler, or they blindly follow what they did last year. In cases where they do attempt mixed provisions, the allocation is often arbitrary, say a 50/50 split, or based on rough assumptions that don’t reflect your actual import/export flows.

Even well-meaning brokers tend to operate within manual spreadsheets or legacy systems that don’t support real-time optimization. That means they don’t test every valid scenario, simulate every outcome, or cross-reference which allocation unlocks the most value.

At Pax, we've engineered our system to do exactly that. We ingest all your manufacturing records, raw material imports, and export manifests, then simulate every permissible combination across unused and manufacturing claims. We identify the allocation that delivers the highest total refund, while staying fully compliant with the rules around double-counting and valuation.

Mixed provisions are not edge cases, they're a reflection of how modern companies actually move goods. And the difference between a naive allocation and a strategic one can mean the difference between average results and exceptional outcomes. If you're not thinking about how to split your claims, you're almost certainly leaving money on the table.

Why most brokers don’t maximize refunds

If you’re already working with a duty drawback broker, or you’re a broker yourself, you might assume your claims are being handled properly. And in a compliance sense, that’s likely true. But being compliant is not the same as being optimized.

Most brokers rely on legacy tools that can’t optimize

The majority of brokers today still use DutyCalc, a software tool first developed in the early 1990s. At the time, DutyCalc was a breakthrough: a calculator that helped customs brokers comply with U.S. Customs’ Form 7553 and track import/export line items by hand.

But that’s the problem. It’s a calculator—not an optimizer.

DutyCalc wasn’t built to simulate multiple scenarios or dynamically allocate entries across provisions like J1 and J2. It can’t adjust for refund-maximizing configurations or run matching strategies across massive datasets. It takes your inputs and gives you a number, based on basic substitution logic and FIFO assumptions. In other words it’s static math in a dynamic world.

And yet, most customs brokers still use it. Not because they’re lazy but because there hasn’t been an alternative. Until now.

Why optimization is so much harder than filing

Let’s say your company imports 1,000 unique product lots a year, and exports 750. That’s 750,000 potential import-export pairings. If you’re operating under J2 substitution, every combination must meet specific rules:

- The export must happen after the import

- The goods must share a qualifying 8-digit HTS code

- The refund is based on the lower of the import or export value

- Entries cannot be double-used across J1 and J2

That’s a huge combinatorial problem. Brokers using spreadsheets or calculators often give up and rely on simple heuristics—rules like “match earliest import with earliest export” or “match by value, then date.” These shortcuts are fast and legally sufficient, but they don’t produce the best outcome.

In math terms, this is a constrained optimization problem. You’re trying to maximize total refund value while satisfying legal constraints (timing, value limits, HTS match requirements, etc.). You need to test thousands—sometimes millions—of permutations and simulate outcomes to choose the one that yields the greatest possible refund.

It’s not a task a human can do manually. It requires real computational power.

The problem of dimensionality

Drawback optimization isn’t just a two-variable problem. It operates across many interlocking dimensions, including:

- Time (import and export dates)

- Product equivalency (HTS code, quality, form)

- Value (declared costs, which can vary wildly across imports)

- Quantity (units, lots, and sub-lots)

- Provision eligibility (J1, J2, manufacturing, or a hybrid)

Imagine trying to solve a Rubik’s cube where every twist changes the shape of the cube itself. That’s what it’s like to optimize drawback without automation. You’re not just solving for a simple output—you’re navigating an evolving maze of constraints, all while ensuring full compliance with all federal regulations.

That’s why most brokers default to simple pairings. They process claims the fastest way they can, rather than the most effective way.

Pax was built to solve the optimization problem

Pax’s duty drawback system is designed from the ground up for applied optimization. Instead of hand-matching lines or relying on FIFO logic, our platform ingests structured import and export data, assigns metadata across all dimensions, and simulates every legal match scenario across provision types.

Using operations research techniques like constraint programming, linear optimization, and integer simulation, we can evaluate thousands of combinations quickly. Then file only the one that yields the maximum refund.

This is why our clients regularly receive ten times more in refunds than with their previous brokers. Not because those brokers weren’t doing their jobs, but because their tools were never built to solve this kind of problem.

In optimization, “good enough” leaves money behind

The customs system doesn’t penalize brokers for filing claims that leave money on the table. As long as the claim is accurate and timely, it’s considered compliant. But what that means is that thousands—sometimes millions—of dollars in eligible refunds go unclaimed every year, simply because nobody did the math.

If you’re an importer, this means you’re missing out. If you’re a broker, this means your clients could be getting more, and might eventually move on if they realize that.

Pax doesn’t guess. We simulate, solve, and maximize.

The hidden value of optimized duty drawback

Duty drawback is one of the most powerful, but underutilized, ways to recover money in international trade. But simply filing a claim is not the same as maximizing your refund. True optimization requires a deep understanding of provision strategy, advanced duty drawback calculation, and the ability to simulate and solve for the highest-value outcome—across thousands of data points and regulatory constraints.

Most brokers stop at what’s fast and compliant. Pax goes further.

Our duty drawback system doesn’t just file drawback, we run complex optimization models to ensure you’re reclaiming every dollar you’re legally owed. We analyze your J1 and J2 eligibility, avoid substitution traps, and reconfigure claims across provision types to uncover the highest refund possible.

If you’re wondering how to maximize duty drawback refunds, you have to start with the right foundation. Most firms are using outdated tools and relying on heuristics that leave refunds on the table. Pax was built differently, from the ground up, to solve this as an engineering problem, not a paperwork task.

Ready to see how much more you could be getting back?

Talk to our team. We’ll show you the difference optimization makes.